About Us Güral is an art

More than porcelain

Craftsmanship, art, quality, and success come together in an unparalleled brand: Güral Porcelain. Since 1989, we have focused on producing flawless porcelain, always questioning how to achieve better. Every time we found answers to these questions, we were rewarded with success. We have become one of the most respected porcelain brands in our country and around the world. In order to carry the centuries-old craftsmanship culture and aesthetic heritage of our land to new generations, we have created a new porcelain culture. This culture has been adding value to both our country and our employees from the very beginning. To contribute to the porcelain culture, we conduct new R&D studies every day in our production facilities.

Combining craftsmanship and art, we prepare the future options we create for the spirit of the past with modern production techniques and traditional handcraft methods with great care. For us, porcelain is like an endless success story that grows as it is told, expanding as it is produced, and spreading to everyone.

Definition of perfection

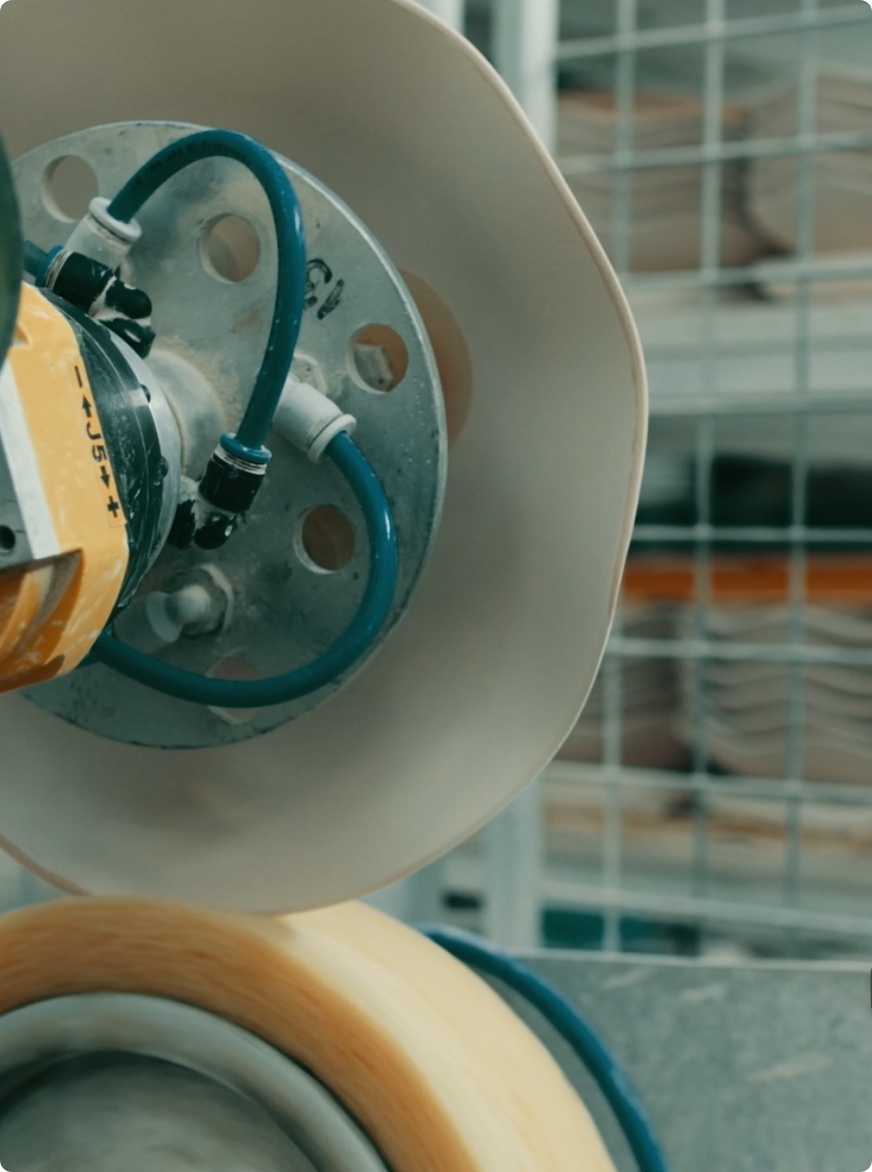

Güral Porcelain has been producing flawless porcelain since 1989 by combining traditional craftsmanship knowledge and aesthetic understanding with contemporary production techniques. This qualified production is carried out not only within the country but also in 60 different countries, over a total area of 275,000 m2, of which 75,000 m2 is closed. The quality of the flawless porcelain is certified by TSE and ISO 9001 Quality Assurance Standards. By using both a deep-rooted corporate culture and modern production techniques simultaneously, Güral Porcelain has earned a special place in the industry. Güral Porcelain, which develops robotic solutions for special forms, has made significant improvements in both quality and production capacity with this manufacturing technique.

In addition to its R&D studies, Güral Porcelain, a brand with high environmental sensitivity, provides heat recovery in many of the furnaces in its production facilities. Heat that would be released into the environment is transferred to suitable areas within the factory where it can be reused, leading to improvements in energy savings and carbon monoxide emissions.